Mold Remediation using Dry Ice

Mould and Bacteria can cause a great amount of health issues when found in everyday living and working spaces.

Common causes and habitats for mould growth include floods, leaks, plumbing problems, elevated humidity, and inefficient cleaning. Allergies are on the rise, fungal infections have become common and contamination has become a risk in production facilities, restaurant kitchens and product and food storage facilities.

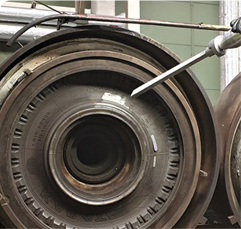

Dry Ice Blasting removes the matter that can promote mold growth along with removing existing mold with high pressure blasting at – 78ºC freezing temperatures.

Restoration of contaminated materials is successful for industries like residential building, construction and processing plants and will save time and money without the need for disassembly, reducing secondary waste clean up and restoring rather than replacing materials.

You are benefitting from Dry Ice Blasting, because:

• 60% to 80% faster job completion.

• Safer, cleaner, easier and faster.

• Superior detail cleaning in tight spots and around obstructions.

• Complete removal of mold from tight angles in trusses, joists and corners.

• Enables cleaning around wiring and plumbing without damage.

• Thorough mold spore removable.

• Easy clean-up, with reduced waste disposal.

• Surface left completely dry, contaminant free and structurally intact.

GET AN AMAZING RESULT IN NO TIME!

DRY ICE CLEANING WITHOUT WATER OR CHEMICALS.

DRY ICE BLASTING SERVES MANY BENEFITS

1. Cleaning with a Natural Substance

Dry Ice Blasting uses Dry Ice Pellets made from the same substance used to carbonate beverages. This method does not generate secondary waste as does sand, soda, water, or grit cleaning. Dry Ice Blasting also replaces chemical and solvent based cleaning.

2. Safe on Electrical

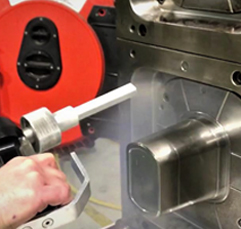

This versatile process cleans heavy buildup without damage to sensitive areas like electrical components, switches, wiring, photo electric sensors, and more.

3. A Thorough, Deeper Cleaning

Since Dry Ice Pellets manage to reach every nook and corner of the equipment it cleans more deeply and effectively.

4. No Damage

Dry Ice Blasting is completely dry, non-abrasive, non-toxic and non-corrosive . It quickly removes most contaminants without damage to switches, panels, lines, tubes, wiring or belts, HVAC equipment and is safe to use on electrical.

5. No Down Time

The process is very fast and dry. The dry ice disappears on contact and can be performed on-line without disassembly and without need for drying time.

Dry ice blasting serves many benefits cleaning without water or chemicals

Natural Substance

Deeper Cleaning

Safe on Electrical

No Damage

No Down Time

OUTSTANDING INDUSTRIES

We provide detailed insight into the benefit of cleaning with dry ice for the many industries

where dry ice is the preferred cleaning method.