Fire Restoration

Primarily dry ice is not adding any water or chemicals to the areas where sensitive parts have been affected. Using crushed dry ice pellets at low pressure even fine electronics can be cleaned without any damage. And dry ice will remove chlorides that has moved with the smoke and which otherwise would be a risk of starting a rapid corrosion on metal parts both external but also inside electronics.

Dry ice is also known to reduce or eliminate burnt smells and bad odors.

At higher pressure the dry ice can also remove charred surfaces and at any pressure between soft for sensitive parts and aggressive to remove charred surfaces the blaster can be adjusted to remove smoke and soot from wiring, electrical boxes, ductwork, plumbing, conveyors, motors etc. All without introducing secondary waste or causing damage.

Benefits:

• Avoids the mess of soda or sand blasting.

• Avoids the use of hazardous chemicals.

• Reduces the burnt smell from fire.

• Eliminates secondary waste.

• Causes no additional water damage.

• Is safe for cleaning electrical components.

GET AN AMAZING RESULT IN NO TIME!

DRY ICE CLEANING WITHOUT WATER OR CHEMICALS.

DRY ICE BLASTING SERVES MANY BENEFITS

1. Cleaning with a Natural Substance

Dry Ice Blasting uses Dry Ice Pellets made from the same substance used to carbonate beverages. This method does not generate secondary waste as does sand, soda, water, or grit cleaning. Dry Ice Blasting also replaces chemical and solvent based cleaning.

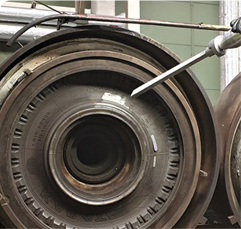

2. Safe on Electrical

This versatile process cleans heavy buildup without damage to sensitive areas like electrical components, switches, wiring, photo electric sensors, and more.

3. A Thorough, Deeper Cleaning

Since Dry Ice Pellets manage to reach every nook and corner of the equipment it cleans more deeply and effectively.

4. No Damage

Dry Ice Blasting is completely dry, non-abrasive, non-toxic and non-corrosive . It quickly removes most contaminants without damage to switches, panels, lines, tubes, wiring or belts, HVAC equipment and is safe to use on electrical.

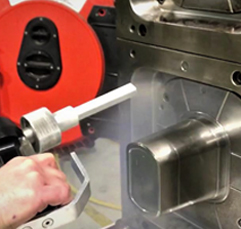

5. No Down Time

The process is very fast and dry. The dry ice disappears on contact and can be performed on-line without disassembly and without need for drying time.

Dry ice blasting serves many benefits cleaning without water or chemicals

Natural Substance

Deeper Cleaning

Safe on Electrical

No Damage

No Down Time

OUTSTANDING INDUSTRIES

We provide detailed insight into the benefit of cleaning with dry ice for the many industries

where dry ice is the preferred cleaning method.