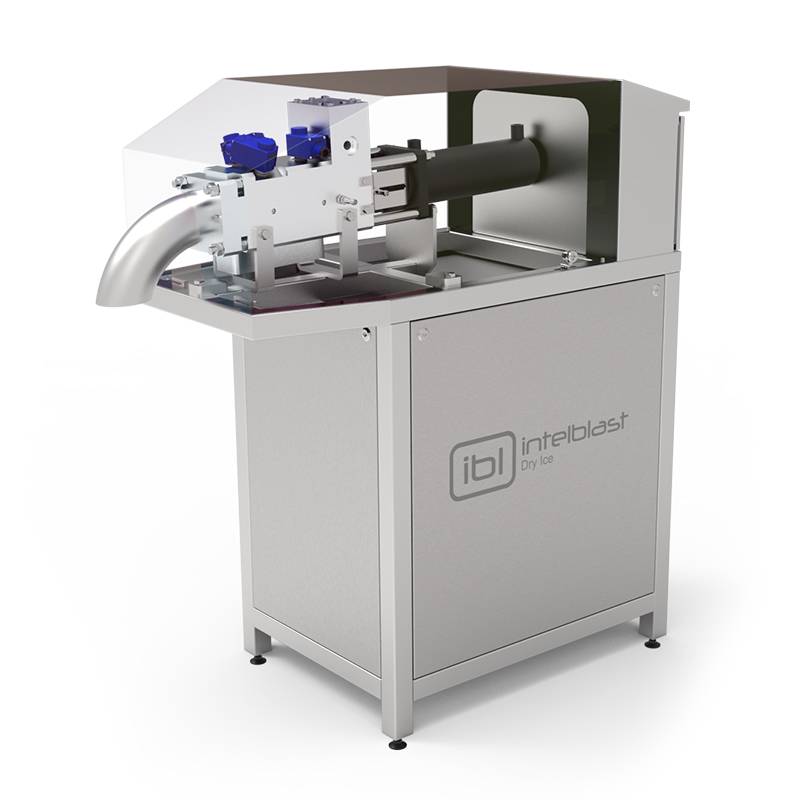

With an output of 120 kg or 240 kg per hour the DIP120 and DIP240 will cover the needs of most stand alone, in-house production of dry ice for cleaning or cooling.

Smart engineering with internal tubing for the flow of the liquid carbon dioxide not only reduces production cost, which in return benefits our customers, but also increases the efficiency and make it possible to have a start up of dry ice pellet production in less than 1 minute.

TOUCH PANEL

The pelletizer is operated by the touch panel that also allows for individual settings to optimize production capacity. An input/output menu allows for a complete system check with a functionality check of each valve and components in the machine.

ADVANTAGES

In house production of high-density dry ice pellet offers many advantages:

• Delivery/production with short notice

• Reduction in losses, by manufacturing only what is needed

• Fresh pellets for better cleaning or cooling

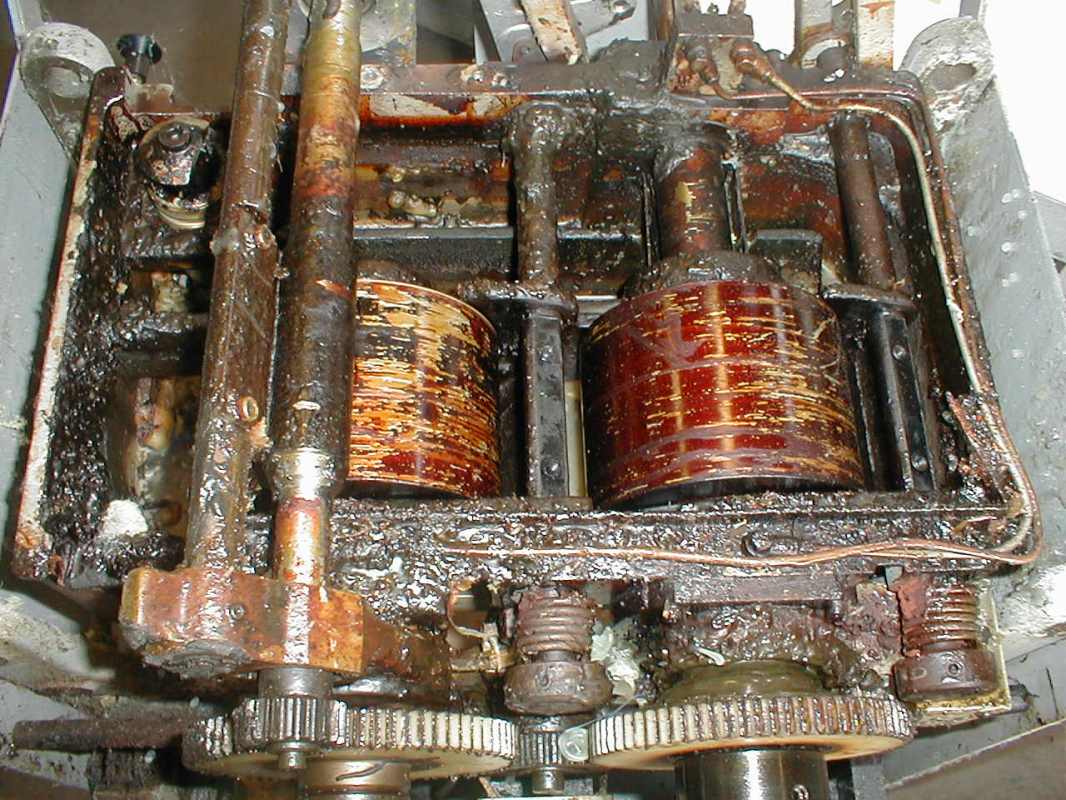

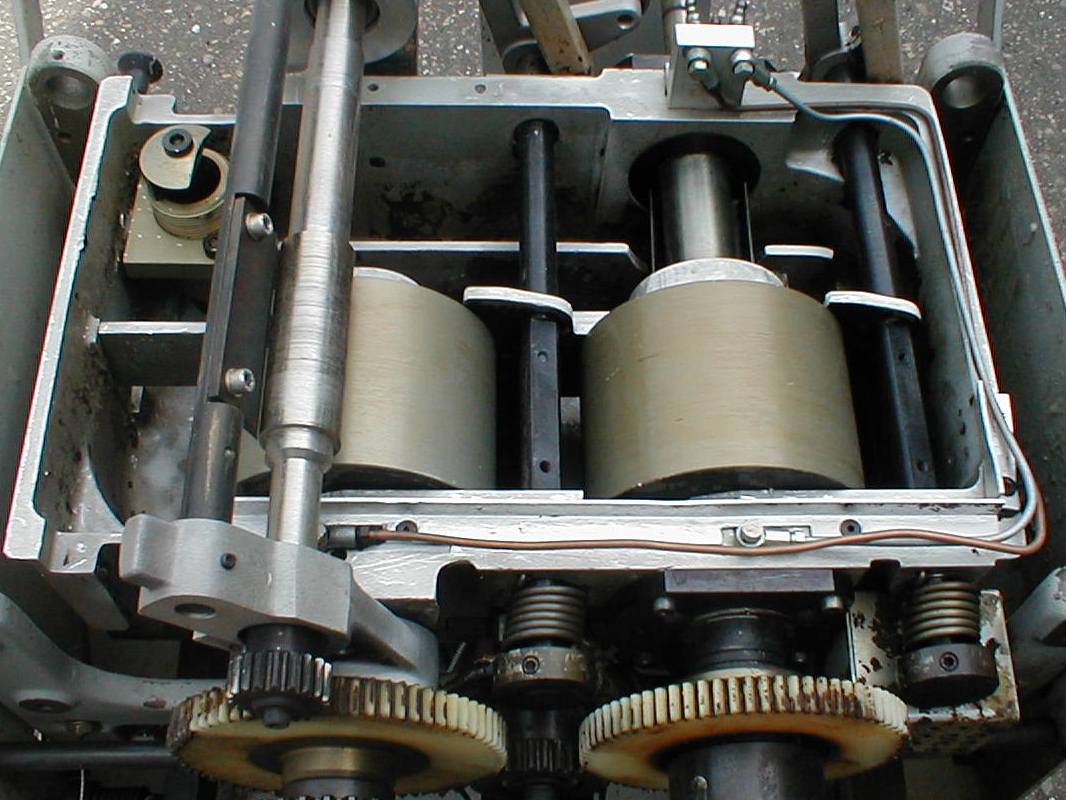

The important factors, when considering purchasing a dry ice pelletizer are, besides the obvious fact that you want lowest capital investment cost, that you get a machine with well-known reliable components, with the minimum of maintenance cost.

CO2

Besides a durable 100% stainless steel cabinet, we only use components from Danfoss, Siemens and a highperformance hydraulic power unit are key components for the operation of the Intelblast pelletizers.

When manufacturing dry ice the conversion of liquid CO2 to dry ice is about 2,5 kg of liquid CO2 to make 1 kg of dry ice.

The special design for supplying liquid CO2 to our press chamber, brings the conversion closer to 2,2. That of course also requires that the installation of the LCO2 tank and supply piping from the tank to the pelletizer is done according to our guidelines.

It is important to stress that NO CO2 is specifically produced to manufacture dry ice. The CO2 used for dry ice production comes as a bi-product from other process like ethanol, biomass, ammonia or even from natural sources such as underground volcanos. This makes dry ice the true environmentally green solution for transport, cooling and cleaning.

DESIGN

The stainless-steel cabinet is designed so that it easily can be moved around with a fork-lift, which facilitates regular, easy cleaning around and under the machine. Larger removable panels gives clear & spacious access to all components inside the pelletizer and makes routine maintenance time and cost efficient.

The small build size (110×70 cm) takes up very little floor space and with the delivery pipes extended out in the front of the unit allows for a dry ice box to be centered under the pelletizer to allow an even production without having to shuffle dry ice from one end to the other.

Who can benefit from having in house production of dry ice?

• Customers and consumers of dry ice with long transport times and distances to supplier.

• Customers who require short response time from ordering to use.

• Customers where the pay back calculation shows significant savings.

Production capacity

120 kg/hour @ 16-18 bar

Standard extruding plate

3 mm

Voltage

400 V – 50 kHz (16 Amp)

Power consumption

5,5 kW

Dimensions L x W x H

110 x 70 x 170 cm

Weight

450 kg empty

The pelletizer can operate with LCO2 tank pressure from 19 to 25 bar. The piping from tank to pelletizer must be cryogenic insulated piping, so a minimal distance from tank to pelletizer is ideal.

Nozzles included

240 kg/hour @ 16-18 bar

Standard extruding plate

3 mm

Voltage

400 V – 50 Khz (16 Amp`)

Power consumption

5,5 kW

Dimensions L x W x H

110 x 70 x 170 cm

Weight

500 kg empty

The pelletizer can operate with LCO2 tank pressure from 19 to 25 bar. The piping from tank to pelletizer must be cryogenic insulated piping, so a minimal distance from tank to pelletizer is ideal.

Do you have questions or can’t find what you’re looking for?

No problem, our specialist will assist you without obligation

Dry ice blasting serves many benefits cleaning without water or chemicals

Natural Substance

Deeper Cleaning

Safe on Electrical

No Damage

No Down Time